Precision Humidity Control System

Humidity sensor can be optionally

installed inside the all chambers of Micro

Probe System.

The Precision Humidity Control System

consists of a two-channel MFC, DI water

bubbling bath and humidity control

software.

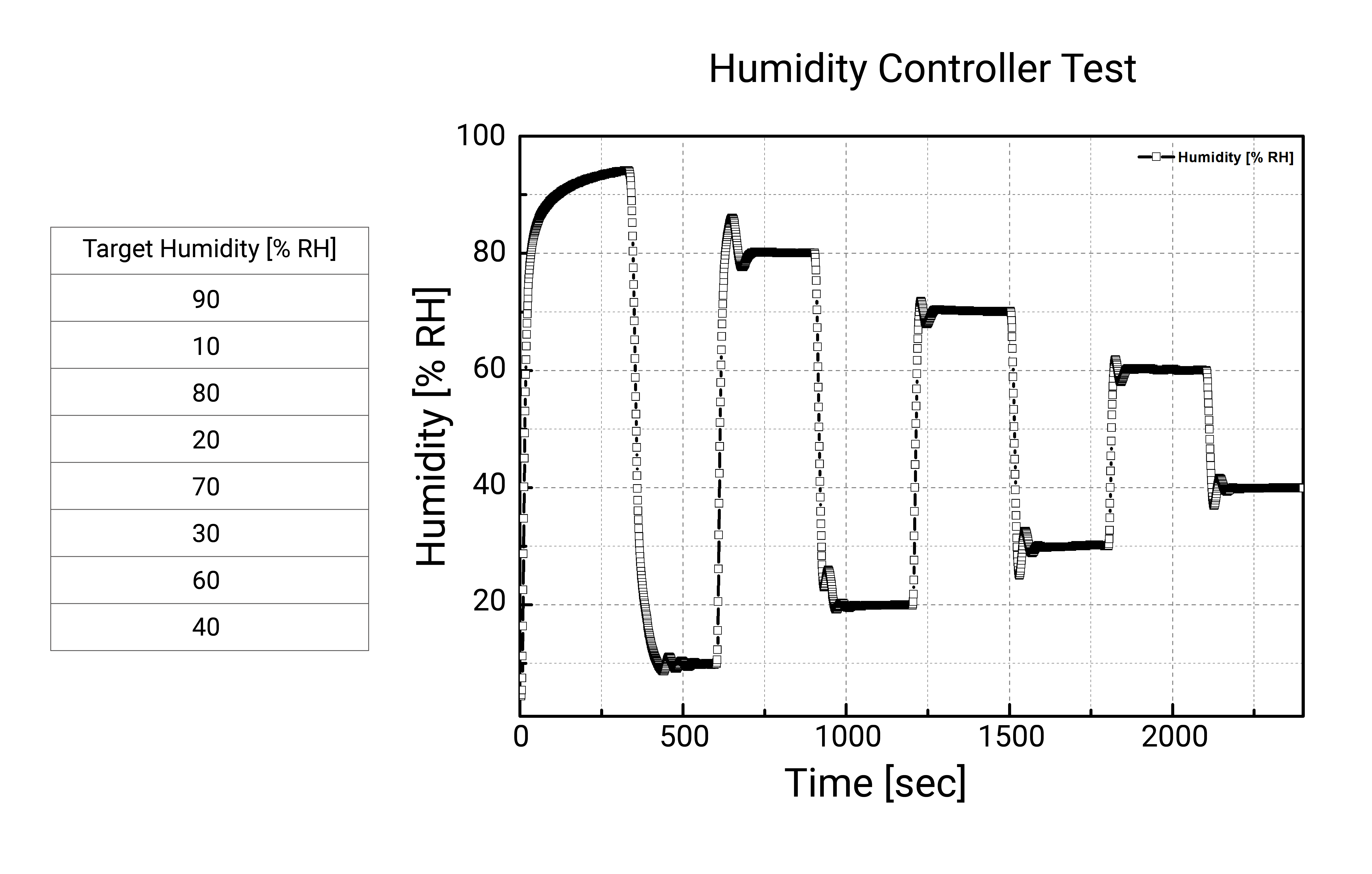

Precise control of relative humidity can be

quickly achieved PID control method.

| General Specification | ||

|---|---|---|

| Manufacturer | Nextron Corporation | |

| Product Name | Precision Humidity Control System | |

| Model Number | HCS-2MPT (for PT, LN models) | |

| HCS-2MCH (for CH models) | ||

| Dimensions | W | 300 mm |

| D | 180 mm | |

| H | 355 mm | |

| Weight | 7.5 kg | |

| Input Power | 100 - 240 VAC, 50/60 Hz | |

| External Port | Communication Interface | USB 2.0 Type B |

| Gas Flow Inlet / Outlet | Swagelok tube fitting ¼“ | |

| Number of MFC Unit | 2 ea | |

| Technical Information | |

|---|---|

| Carrier Gas | N2 (recommanded), Air, Ar |

| Bubbling Bath Volume | 200 cc |

| Total Flow Rate | 1000 SCCM* |

| Gas Flow Range | 0 - 1000 SCCM** |

| Flow Rate Accuracy | ±2 % of full scale |

| Humidity Control Range | 4 - 95 %RH*** |

| Typical Accuracy of Humidity | 2 %RH (@ 1 - 97 %RH) |

| Normal Ramp Speed | 10 %RH / min |

| RH Resolution | 0.1 %RH |

| Recommended Pressure of Gas Inlet | 10 - 40 psig |

| Required Power | 24 VA MAX |

| Communication type | USB Communication |

*Total flow rate can be selected from 100 to 1000 SCCM.

**Flow Range is determined by total flow rate.

***Ranges may differ depending on experimentation and laboratory temperature.

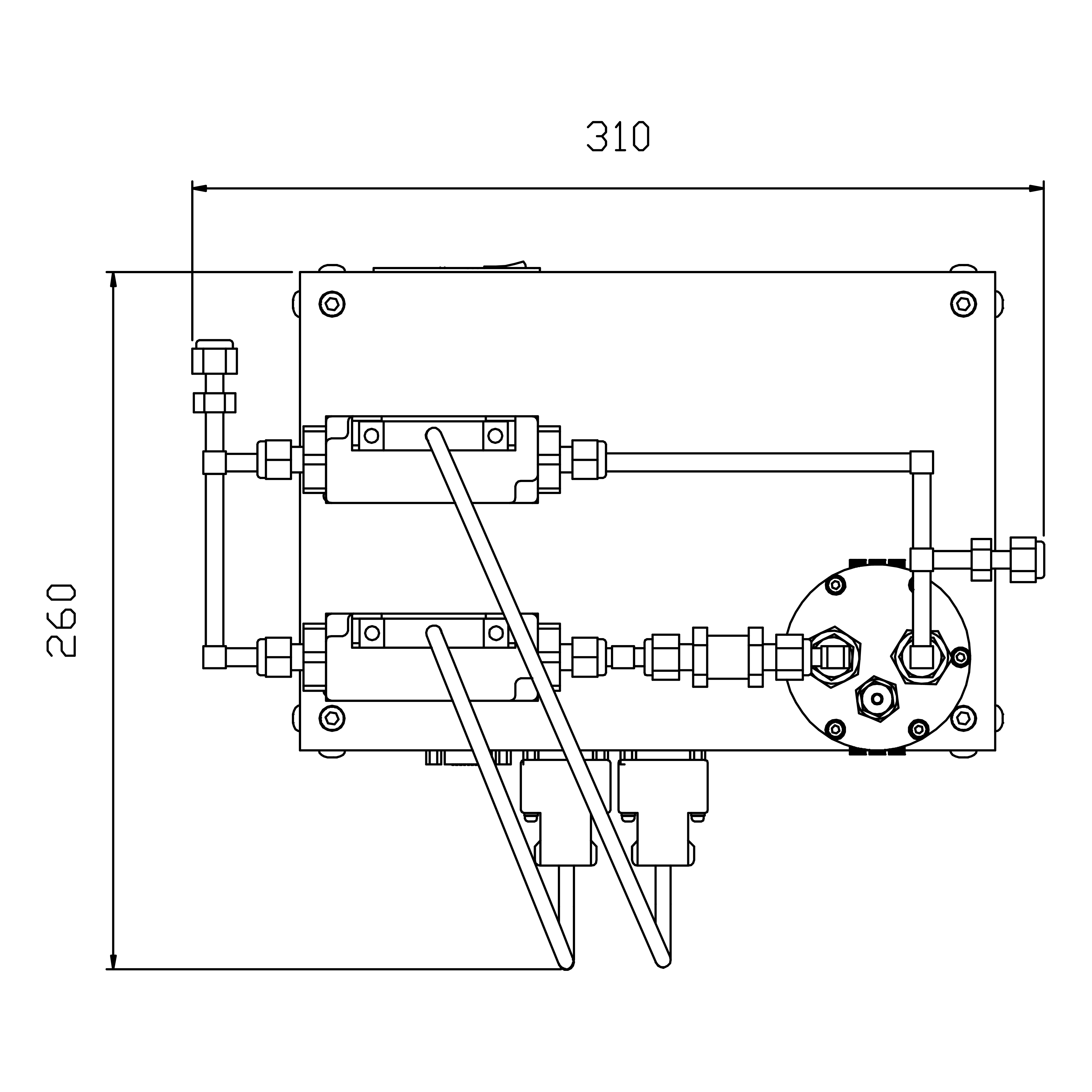

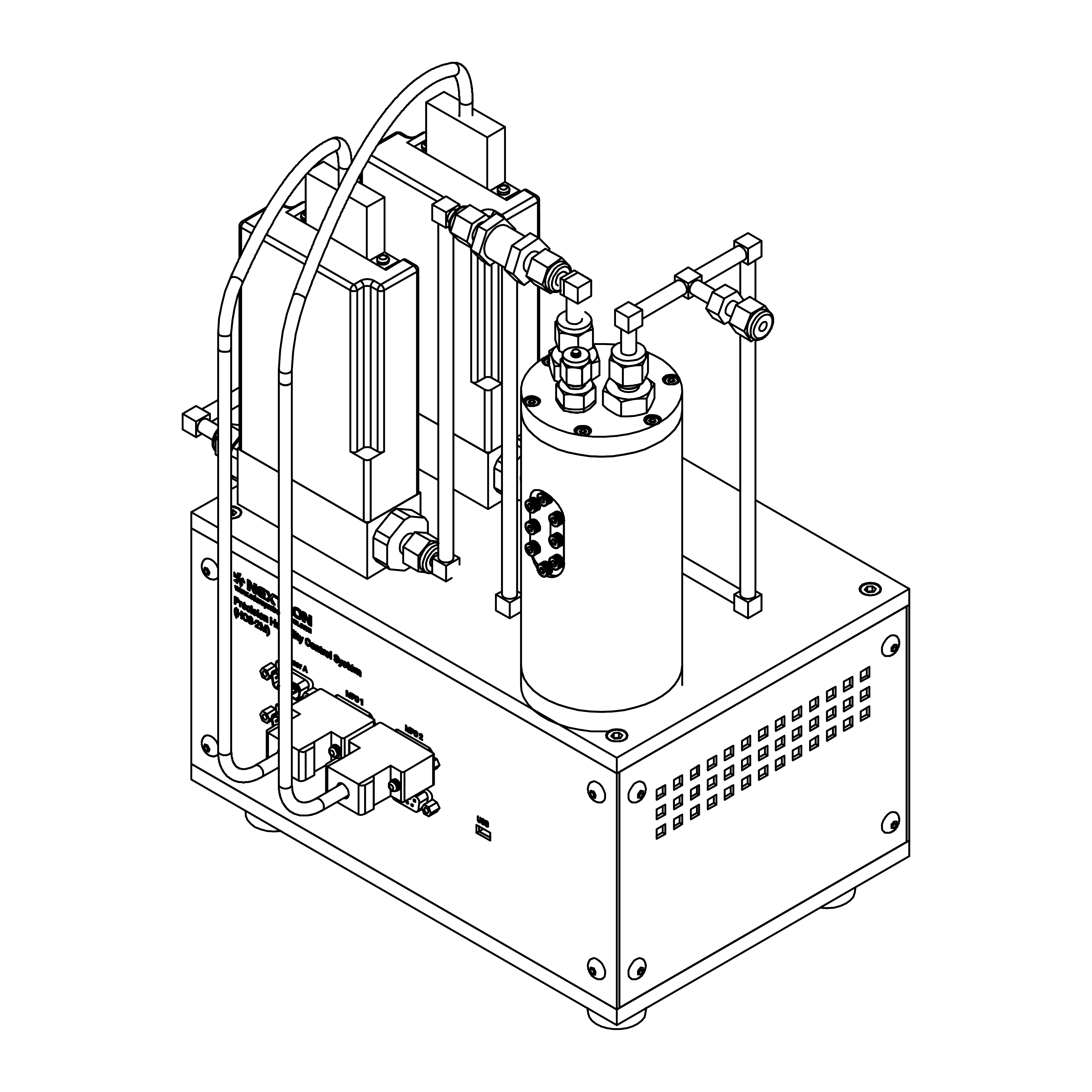

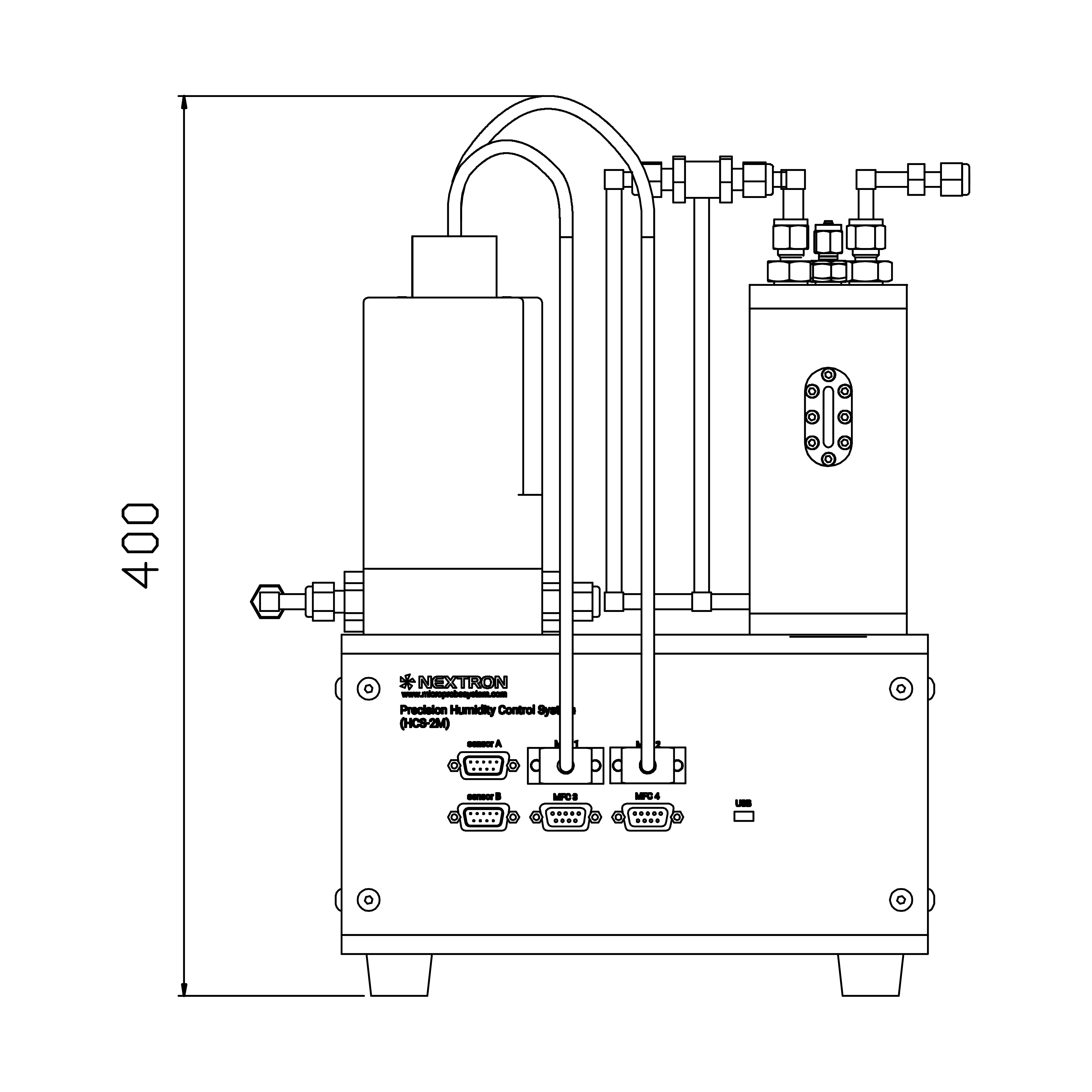

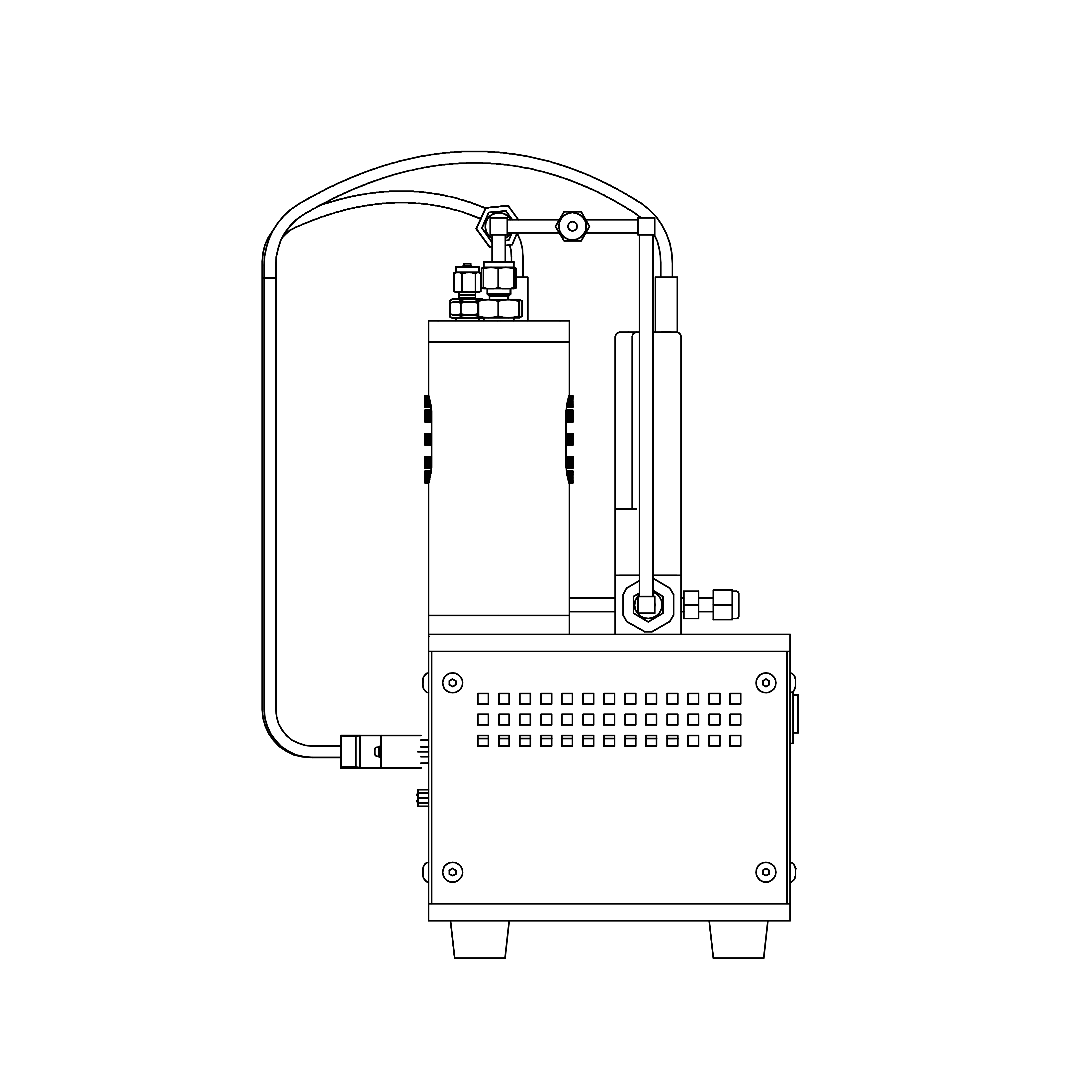

Dimension

(Unit: mm)

|

|

|---|---|

| Top | 3D |

|

|

| Front | Right |

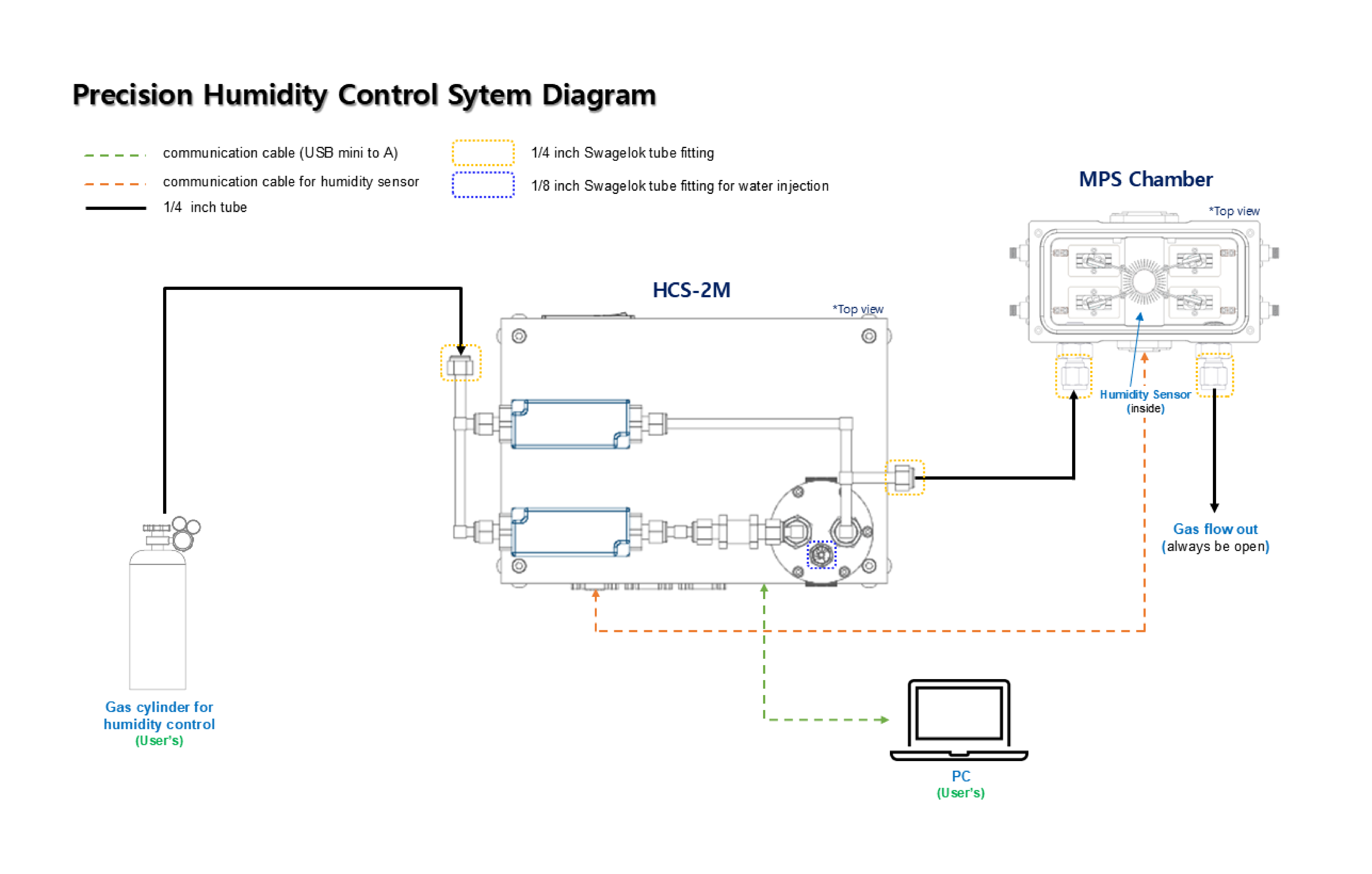

Diagram

Technical Data

Technical Data

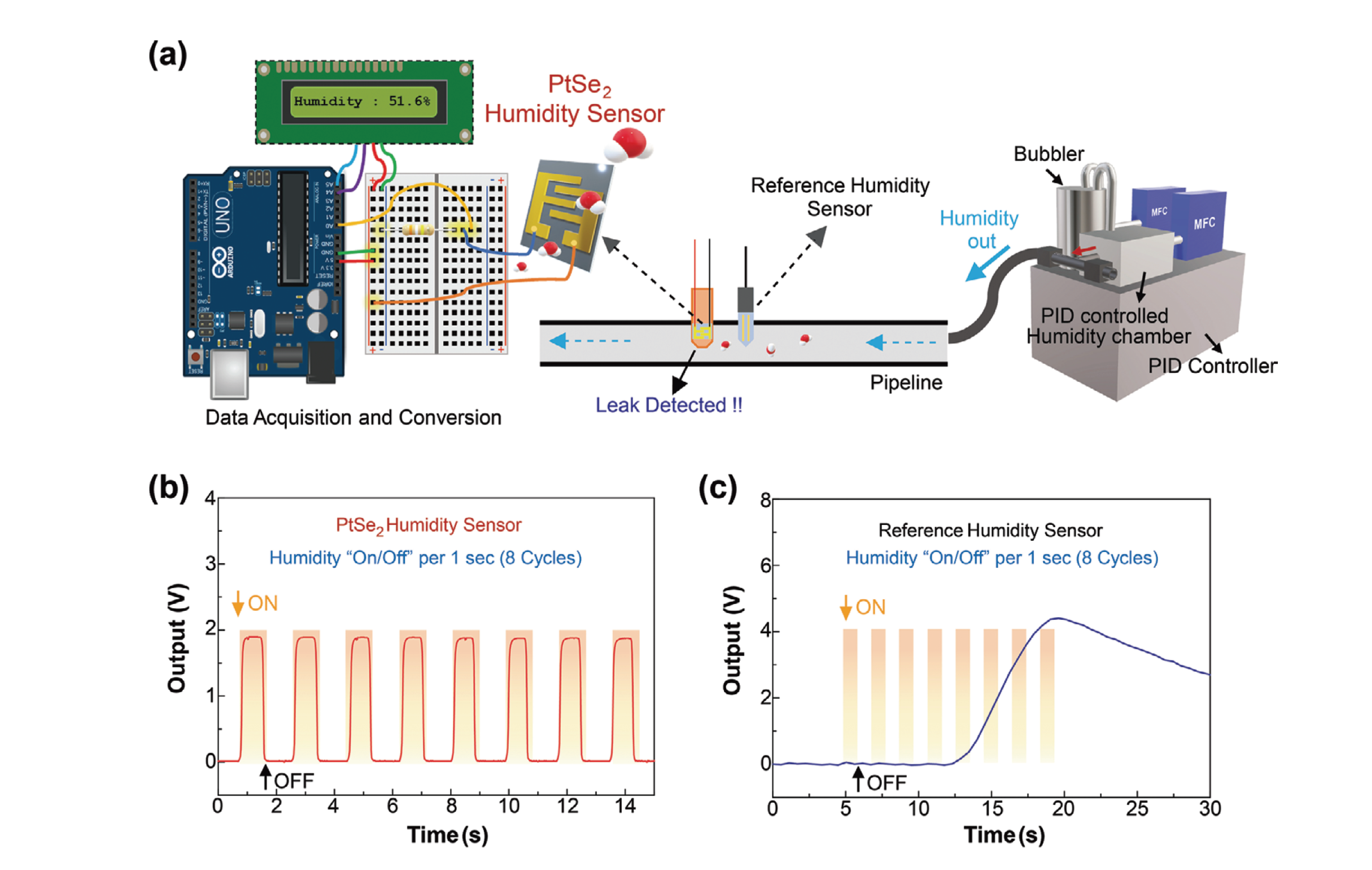

Figure. (a) Schematic diagram of the custom-made early detection of pipeline leak detection system consisting of PtSe2 nanograin-based humidity sensor, (b) precise detection of input humidity pulses by the PtSe2-based humidity sensor, (c) response of best-in-class reference humidity sensor for comparison.

Technical Data

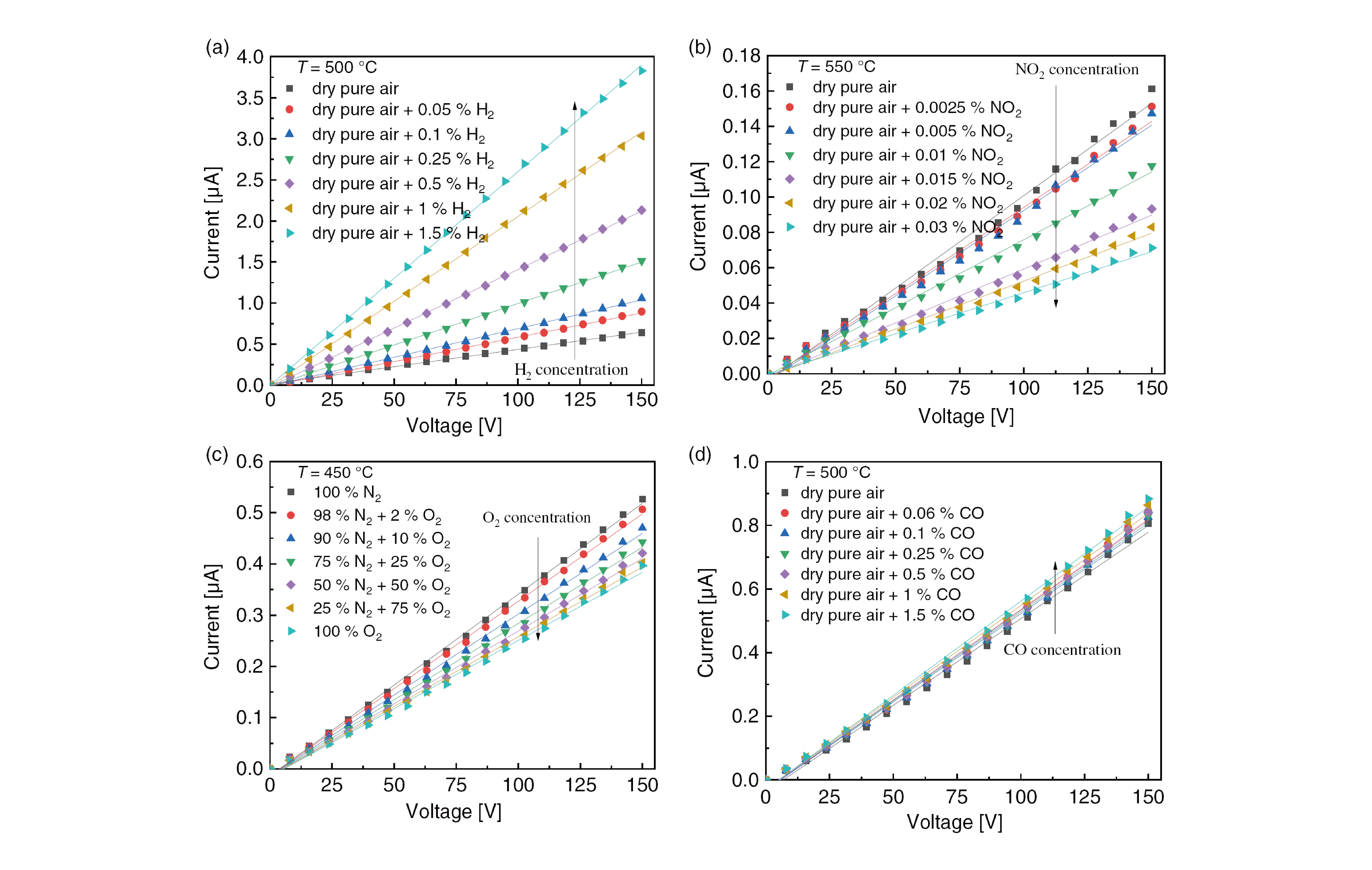

Figure. IV characteristics of ε-Ga2O3 layers when exposed to different concentrations of (a) H2, (b) NO2, (c) O2, and (d) CO.